Machine Tending Robotic Automation with READY

Deploy in hours or days, not weeks or months.

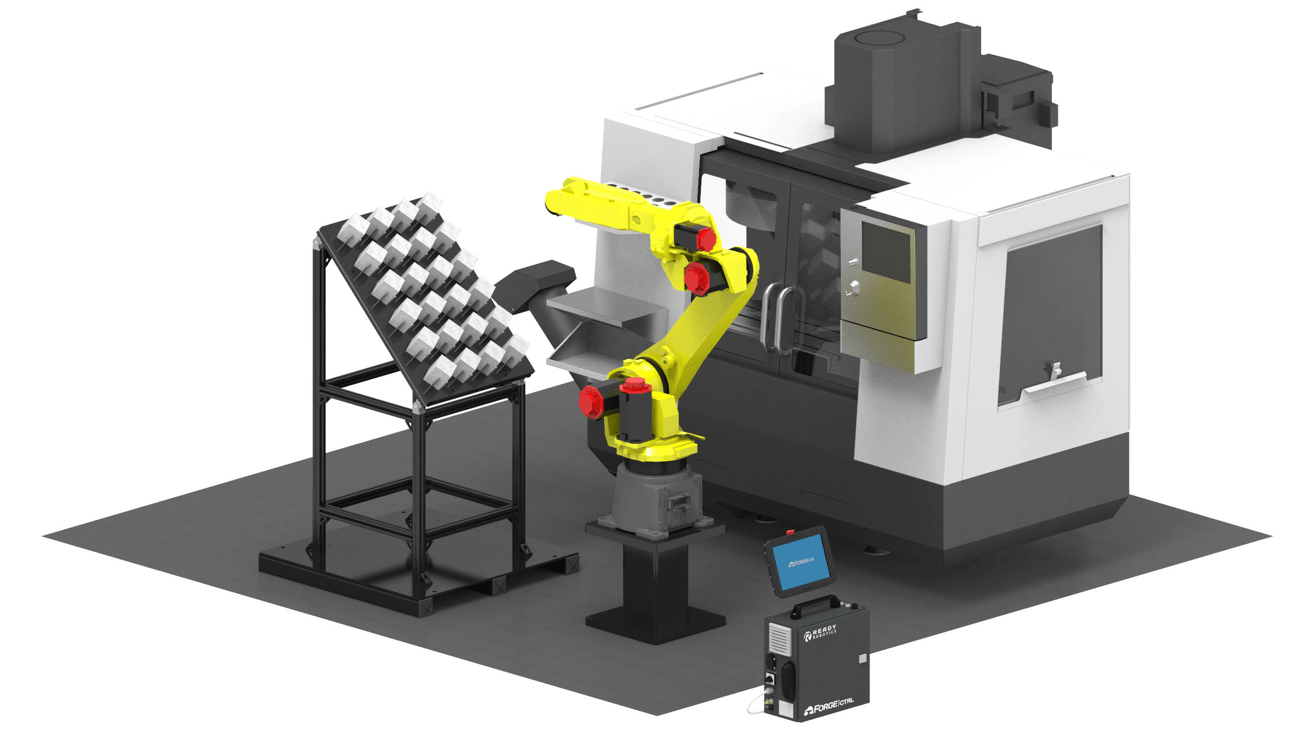

Comprehensive plug-and-play integration of robot arm, PLCs, vision systems, force sensors, machine tools, and other peripherals.

Spread ROI across multiple machine tools with all-in-one mobile automation solution, Forge/Station.

Automate every detail including loading, unloading, door open/close, and cycle start/stop.

Automate new CNC machine tools as well as older model lathes and mills with READY Made tools like button and pedal pressers.

Backup, move and copy your Task Canvas programs and access real-time industrial IoT (IIot) analytics for each work cell with our cloud applications.

Integrate the complete work cell using the READY Controller, Forge/Ctrl, that enables connectivity to your CNC machine tool, PLCs, and other peripherals via built in 24V I/O, EthernetIp, Modbus and pneumatics.

Simplify Automation with Forge/OS

Forge/OS makes it easy to program any robot or cobot, regardless of brand, such as Universal Robots (UR) and FANUC.

Integrate new robots faster and easier, and empower existing workers to manage a diverse fleet of robots.

The visual programming application for automation, Task Canvas gets you into production out of the box in hours vs weeks or months. No lengthy or expensive training in KAREL or URScript required.

Upskill and reskill existing machine operators and other employees who can be trained in hours to program a complete automation solution.

Reduce downtime by enabling virtually anyone in the factory to program and troubleshoot robots.

Dramatically reduce changeover times since program modifications for part changes can be done in hours - not days or weeks.

Fast, Easy, Turnkey Automation.

With complete automation packages for mill, lathe, 3d printers, and stamping press tending, READY Automation Packages are designed to automate every detail of machine tending tasks.

Shop Automation PackagesREADY's controller, Forge/Ctrl runs Forge/OS and provides pneumatics, 24V I/O and Fieldbus protocols.

Choose from many end-of-arm tools including pneumatic, electric and vacuum grippers.

Integrate with many off-the-shelf robots such as FANUC and Universal Robots.

Use Task Canvas to automate the entire workcell including complex robot motions with easy to use flow chart style programming.

Case Studies

See how READY Robotics customers gain a high ROI by using Forge/OS powered solutions to automate their manufacturing tasks.

Need Fast Deployment and Flexibility, Forge/Station Meets your Needs.

Spread ROI across multiple machines with the all-in-one, mobile automation solution, Forge/Station.

Shop Forge/Station