Easily Program and Control Pick & Place Automation

Task Canvas, READY’s user-friendly touchscreen programming application, controls the robot arm and the other actions in the workcell. From moving parts to controlling machines (with or without I/O), Task Canvas empowers almost anyone to implement and maintain pick and place automation.

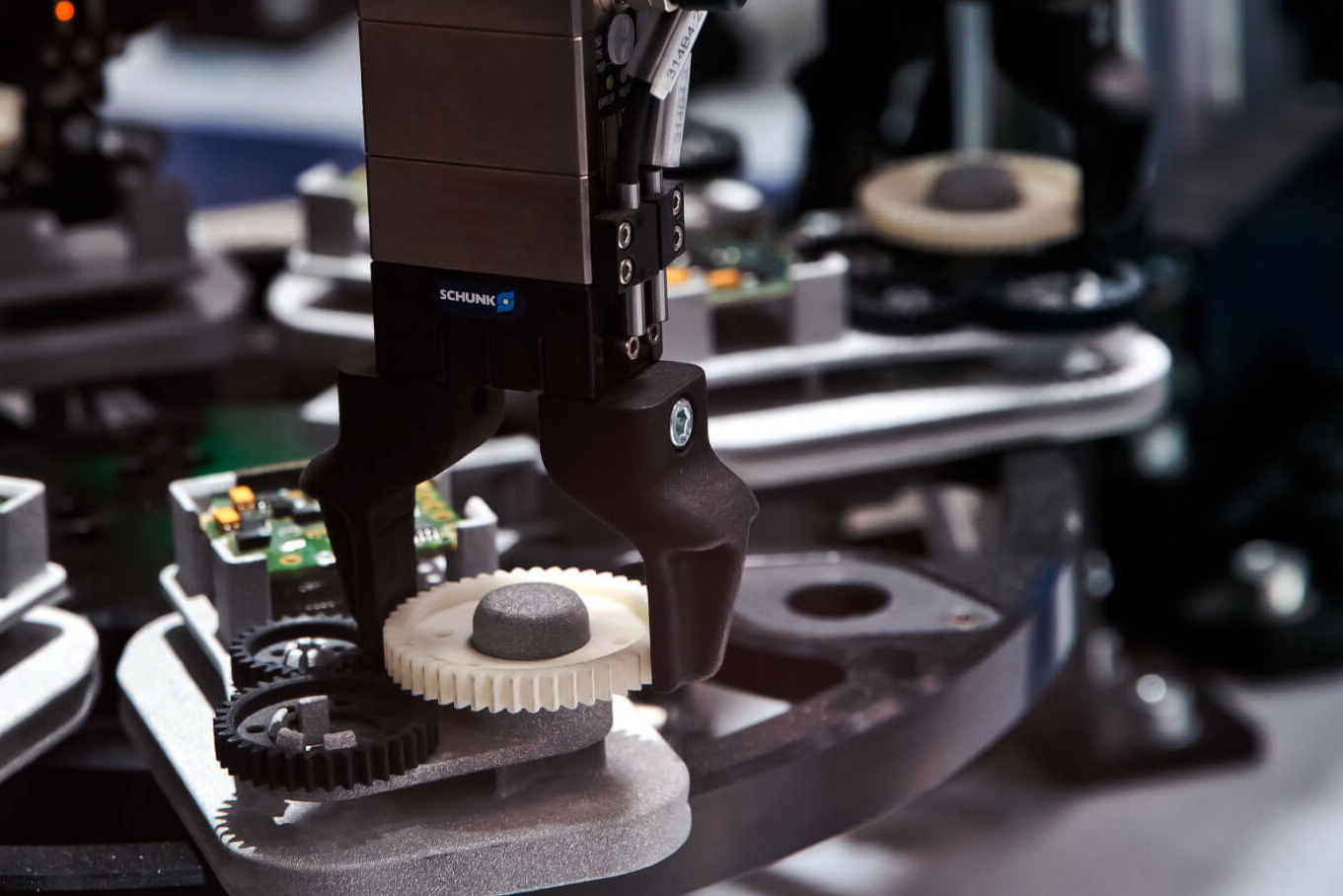

Choosing the right gripper is crucial for a successful pick & place application. Forge/OS allows you to set-up, configure and control a variety of different grippers through the software interface. Loadout and gripper control is intuitive with Task Canvas.

End effector pneumatic control blocks can be used to open or close a pneumatic gripper attached to the end of the robot arm.

Optimizing robot movements is important for a successful application. The Blend Move block can be used to perform complex movements quickly and fluidly, and prevent collision as the arm moves within its work environment.

Task Canvas allows applications to be responsive to changes in the work environment. The software will respond to upstream changes in the application while placing downstream parts.

The Jog block can be used to move parts precisely in a specific direction. This allows for the part to be picked or placed in a repeatable location with a high degree of accuracy.

The I/O Output block can be used to communicate with peripherals in the work environment. Sending signals to the conveyor belt to carry the parts onto their next destination.

Part Counter blocks can be used to define how many times a specific action is carried out. This is useful when determining when a load of parts is complete based on how many times a cycle has run.

The Breakpoint block stops the robot and notifies the operator by emailing them a customizable message. Breakpoint blocks are useful for communicating when to load more unfinished parts into a workcell.

- End of line packaging

- Moving material on/ off of a conveyor

- Kitting & assembly preparation

- Material handling

- Machine infeed

- Removing parts from a laser cutter

Getting started has never been easier

Our deployment process has been designed to save you time and money. With intuitive, user-friendly software paired with straightforward documentation, READY systems can be deployed in a fraction of the time of other solutions. More importantly, they can be deployed by the existing team on your factory floor - no integrators or robotics engineers needed!

Choose the right solution

- Pick an automation solution that works for you

- Get help from our knowledgeable staff

Unbox & power on your system

- Follow our easy to use instructions to set up your system

- Get your robot up and running in minutes

Begin Programming in Minutes

- Quickly begin programming your automation with Task Templates

- Easily program complex tasks with intuitive, drag-and-drop visual programming

Run Production Faster

- Program and troubleshoot your tasks easily

- Increase uptime by running robust reliable tasks

ROI in 1 month might not be the norm, but we’ve seen clients achieve exactly that. In general READY clients typically see ROI in under one year. We’d love to discuss your automation project, and how quickly you could expect to achieve a return on your automation investment with READY’s easy-to-deploy, affordable automation solutions.

Forge/OS Automation Bundles

Quickly get up and running with the right automation bundle for your application. With an array of packages featuring Forge/OS pre-loaded onto a purpose-built IPC, or the robust Forge/Ctrl, you’ll have your task automated in no time.

End of Arm Tooling

End-of-arm tools (Grippers) are a critical component of pick and place applications. READY’s automation experts can help guide you through the end-of-arm tool setup and troubleshooting process to ensure your success.

Multitasking Capabilities

Forge/OS enables you to create Subtasks that can run simultaneously to your Main task, checking digital inputs, setting variable values, and running timers. Your task won’t miss a single beat while the robot arm is working hard.

Integrate with Cameras and Sensors

Forge/OS enables you to integrate with camera systems and sensors in your task. This adds to the versatility of your task allowing the arm to pick parts that may not be fed to a repeatable location.

Arnold Packaging

From uncrating to production, Arnold Packaging installed and programmed their first automation task in just a few hours with Forge. They were able to leverage the power of robotic automation without the traditional downsides including: lengthy deployment times, complex changeover, and downtime related to lack of in-house programming/troubleshooting resources.

Watch Video(Automating with READY) has freed our operator from non-value added feeding and allows him to perform quality checks while preparing the next run. I am impressed and the applications I have in mind are vast. There are huge opportunities to eliminate all kinds of manual processes.

The No Code Revolution

Other industries have enjoyed No Code development for years. READY is bringing the benefits of intuitive, user-friendly, No Code programming to industrial automation. Learn about No Code programming, and how it will benefit your manufacturing operation.