Forge/Ctrl is a powerful, flexible, control center for your workcell. Seamlessly connect and control all of the components needed to automate production, including top robot brands, machine tools, and peripherals.

Cross Platform at the Core

Robot programming is no longer a barrier to automation. Forge/Ctrl supports multiple brands of robot arms, bringing the power and ease-of-use of Forge/OS to the robot of your choice.

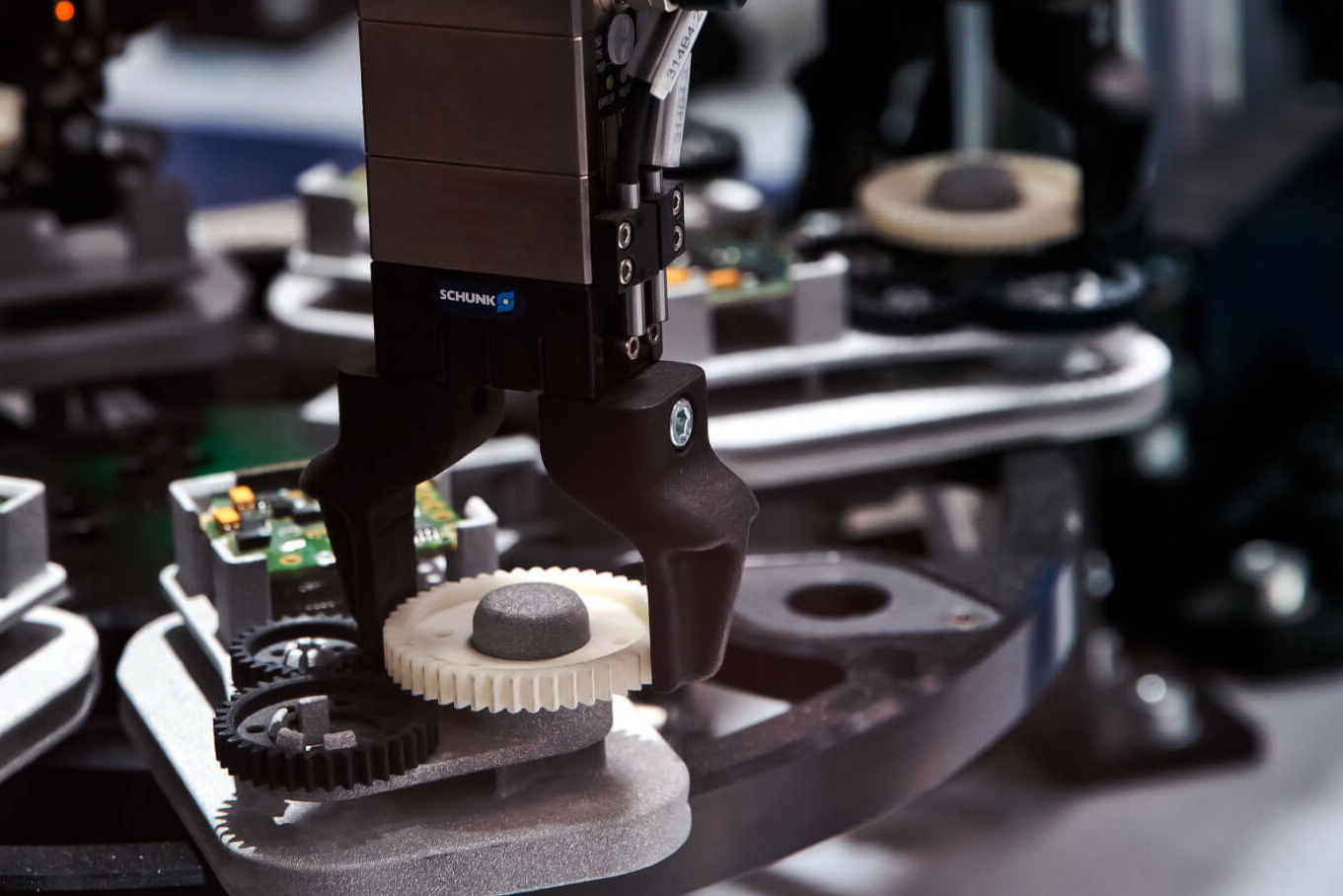

Control Each Component of Automation

Forge/Ctrl sets a new standard for implementing automation - interfacing with robots, machine tools, PLCs, vision systems, force sensors and other peripherals using a standard set of I/O interfaces including pneumatics and fieldbus connectors. This reduces the controls design needed for most automation scenarios.

Ready to Integrate Production Tasks

- Fast Programming with Forge/OS

- Dedicated RS485 port for end effectors

- Dedicated 24V I/O for end effectors

- 8 Controllable Pneumatic Outputs

- 8x 24V Digital Inputs

- 8x 24V Digital Outputs

- Expandable via Robot Controller I/O

- WiFi and LAN connectivity

- IP54 Enclosure Rating

Creating an Industrial Plug-and-Play Ecosystem

With a standardardized set of integration options, READY enables an ecosystem of OEM providers to integrate their hardware with Forge/OS, so manufacturers can plug in a device and be able to instantly program it using a building block within the Task Canvas programming application.

Get the technical specifications of Forge/Ctrl.

Forge/OS

Forge/Ctrl is powered by Forge/OS, the award-winning operating system for industrial automation. Forge/OS’s No Code interface sets the standard in user-friendly robotic and automation programming, and enables all manufacturers to deploy and own their automation - even with no prior robotics experience.

All-in-One Automation

Powered by Forge/OS running on a Forge/Ctrl, the Forge/Station gets you into production in hours - even with no prior automation experience. Boost output, increase uptime, free up valuable workers for more important tasks, and spread ROI across multiple machines. Forge/Station enables any manufacturer to automate now!

Complete Automation Packages

Built around a Forge/Ctrl and powered by Forge/OS, READY Automation Packages are designed to address every aspect of machine tending automation - from robotic arm to EOAT and parts presentation. Automation packages include all hardware and software necessary to automate tasks such as loading and unloading of mills, lathes, 3d printers, and stamping presses