CNC Mill Tending with READY

With easy-to-use programming software, and all-inclusive automation hardware kits, READY makes it easy for anyone to automate their CNC Mill. From picking parts to machine interaction, Task Canvas touchscreen app brings a new level of simplicity to programming a robot. CNC Mill automation has never been easier.

Easily interact with items like the parts presentation drawers by using a blend move. The Blend Move block can be used to perform complex movements quickly and fluidly and prevent collision as you enter and exit your machine tool.

Grid Move Block

Grid Move Block

Save crucial programming time with the grid block. Pick parts out of a grid accurately by setting your corners and input the number of parts. The software autopopulates the rest of the points allowing you to pick in sequence.

The Jog block can be used to move the part in and out of the workholding precisely. This allows for the part to be picked or placed in a repeatable location inside the machine.

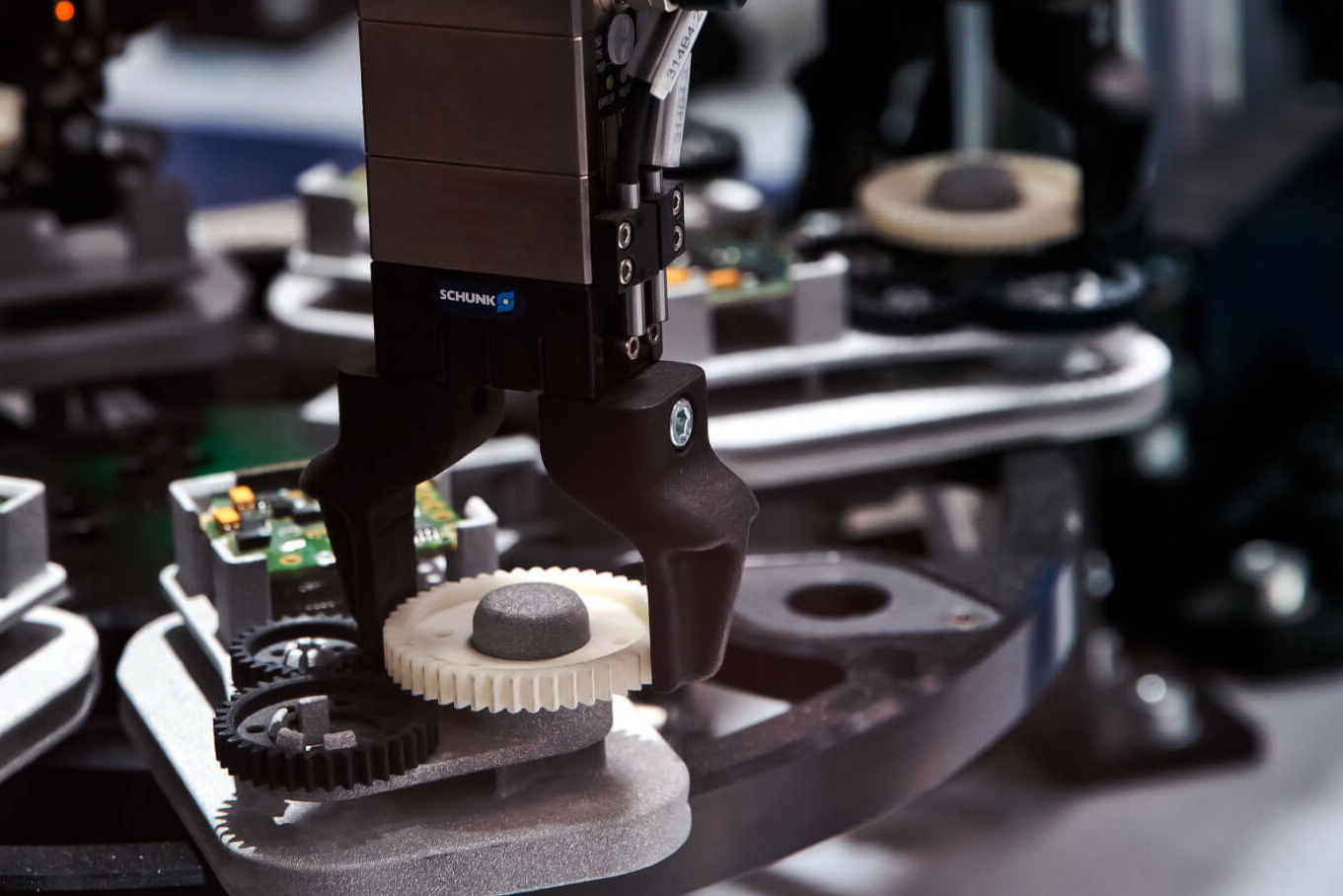

End effector pneumatic control blocks can be used to open or close a pneumatic gripper attached to the end of the robot arm or blow chips and coolant off the part before interacting with it.

The I/O Input block lets Forge/OS receive a signal from the machine once the door is open. This will provide a safe signal when machining is complete, and the robot can go in and grab the finished part.

Gripper blocks can be used to open and close a robot's end of arm tooling (EOAT), which is useful for picking up and placing parts. Forge/OS can be configured to operate both electronic and pneumatic grippers.

Part counter blocks can be used to define how many times a specific action is carried out. This is useful when determining when a load of parts is complete based on how many times a cycle has run.

The Breakpoint block stops the robot and notifies the operator by emailing them a customizable message. Breakpoint blocks are useful for communicating when to load more unfinished parts into a workcell.

How quickly will your CNC Mill automation achieve ROI?

ROI Calculator for CNC Mill Automation

Answer a few questions about your production situation, and get an instant ROI projection.

Turbocharge Programming with Task Templates

Task Templates provide the user with a complete program for an application. This is done by grouping blocks of the programs into containers. You simply have to update blocks relevant to your own application in the graph to have a working program. This allows you to develop automation programs in a fraction of time compared to other programming languages.

Automate Virtually Any Mill

Complete automation packages for CNC mills regardless of brand or age. READY Mill Automation Packages allow for relatively effortless automation of every aspect of mill tending, including end-of-arm tooling, parts presentation, and chip evacuation.

5 Reasons Programming Robots is so Hard

Learn the reason why programmng robots is so hard, and find how leading manufactures are using new technology to solve this problem.

Deploy in Hours or Days

Traditional automation takes weeks or months to deploy. READY Made Turnkey Solutions programmed with Task Canvas often allow for deployment in just one day.

Anyone Can Program

Task Canvas is so easy to learn and use, that most are comfortable programming complex tasks in just a few hours - even with no prior robot programming experience.

Accelerate Changeover

Easily control all aspects of your automation process. Quickly program new tasks, or modify current tasks for parts changeover. Reduce programming task time by 80% with task templates.

ASTec Metalworks

Leading manufacturer of precision-machined components for the aerospace, automotive, and defense industries significantly reduces changeover time on complex, multi-step tasks by automating Mori DMu50 5-axis CNC mill.

Watch VideoThe unbelievably short installation and setup time...enabled us to capture a full shift of additional production running lights out. This gain in production was EXACTLY what we needed to meet a doubling of our aircraft program demands!