The Business

Arnold Packaging is a leading supplier of packaging supplies, custom containers, and packaging automation technologies. On a daily basis, the company produces many different types of boxes, crates, and pallets in different quantities. Whether filling an order for a few dozen or a few thousand, Arnold Packaging has a decades-long reputation for delivering only the highest quality products to their customers.

Task

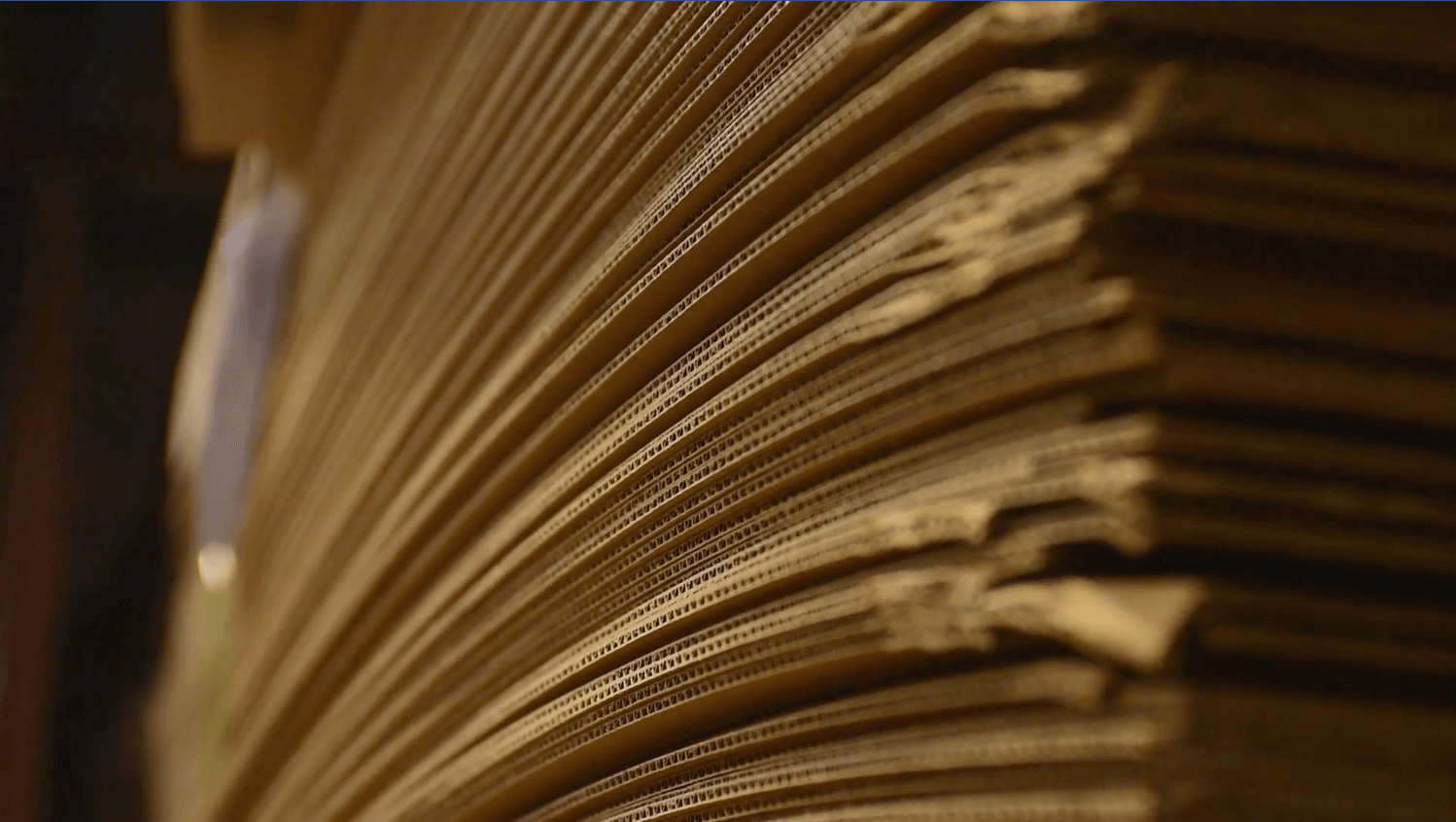

Tending a Magellan Boxmaker machine

The Challenge

Just physically setting up industrial robots traditionally is a complex and time-consuming process. Worse, programming a robot for a production run could then take days. Arnold needed a solution with the flexibility to keep up with ever-changing demands in a fast-paced, high-mix low-volume environment.

The Solution

The Forge/Station, coupled with third-party industrial automation equipment from industry leaders like Universal Robots, Schunk, Robotiq, Piab, and others. Able to be set up in minutes and programmed in a few hours, the Forge/Station allows Arnold Packaging to leverage the power of robotic automation without the traditional downsides including: lengthy deployment times, complex changeover, and downtime related to lack of in-house programming/troubleshooting resources.

The Results

Arnold initially programmed their Forge/Station to tend a Magellan Boxmaker from RJE Machinery. The Forge/Station feeds in cardboard stock from a stack, freeing up a human for more valuable jobs. Tasks are saved in Forge OS, so when the same job rolls around again, no time is wasted reprogramming the robot. Instead, using READY’s mechanical alignment system, a worker at Arnold just rolls the Forge/Station up to the Magellan Boxmaker and goes through the simple alignment process. Five minutes later, the Forge/Station is producing boxes for one of Arnold’s many customers. Given the mobility and flexibility of the Forge/Station, this is only the beginning of robotic automation at Arnold Packaging.