Introduction

The first commercial computer, Univac I, and the first industrial robot, Unimate, were created in the 1950s.

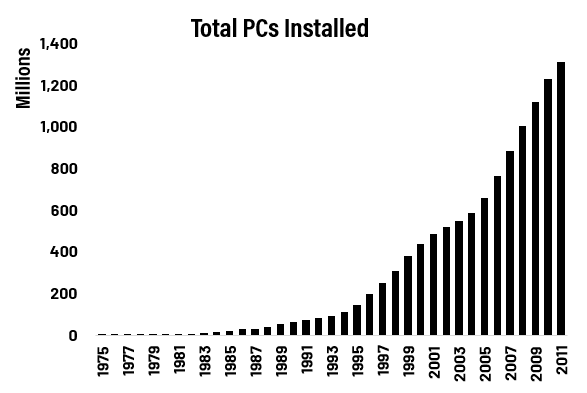

Fast forward and business today is dominated by billions of computers, but robots are still rare. Why is this?

McKinsey (2019) found 88% of manufacturers want to deploy more robots but are struggling with the expense, complexity and skills needed. One major cause of this is software fragmentation, which has stifled innovation in the space. Software is the focus of this article, the first of a series.

The software lessons already learnt in the PC, smartphone and cloud domains can provide valuable guidance as industrial automation modernizes to overcome its challenges:

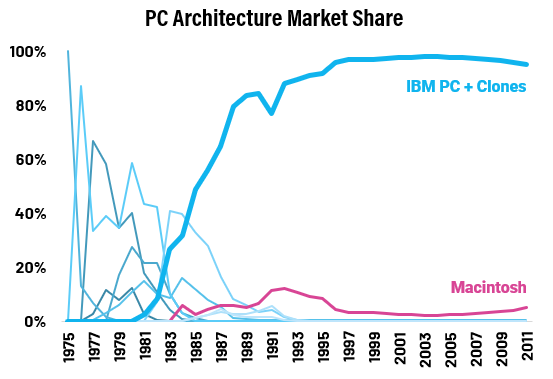

- Software standards enable hardware scale

- Platforms for users and developers drive app innovation and volume

- Data drives ML and analytics which enable continuous optimization

But robotics also has many unique software challenges. It is inherently edge-first - for latency, safety, privacy reasons and more. So our approach is to provide a standard edge API compatible with 3 million factory-proven industrial robots deployed today. This gives enterprises the power to choose exactly how and where their robot data is used.

This is the vision behind the ecosystem that READY Robotics is creating - for both manufacturing enterprises and industry partners alike - and we believe it will dramatically grow the automation market for all.

The human-robot interface

Visicalc (1979) for the Apple II was the first spreadsheet. It was a watershed moment for the microcomputer. Suddenly, business people - not just computer geeks - could use computers to make their jobs easier.

Today computers over 1000x more powerful than the Apple II are in the pockets of billions of people. Innovation in user interface (UI) design have made the smartphone trivally easy to use.

The digital native generation now entering the workforce have high expectations as a result. This shift in UI expectations is already impacting markets like automotive, where touchscreens are becoming a common feature.

However industrial robot UIs still lag behind. These UIs are not only complex, they are proprietary to each robot hardware vendor.

To address this, READY Robotics created a single touchscreen UI for no-code task programming which can replace all of the proprietary devices shown above.

Suddenly, people on the factory floor - not just specialist robotics engineers - can upskill to program all compatible industrial robots within a matter of weeks.

Millions of industrial robots. One API.

The importance of developers has long been understood in the PC and smartphone spaces. Developers create the applications which drive hardware sales which increases the installed base which attracts more developers; this grows the market for everyone and drives value for users.

Abstractions provided by Windows and Android enabled massive scale in the PC and smartphone spaces. It would be crazy if every app developer had to write peripheral drivers and GUI libraries before even embarking on the end-user application. It would be crazier still if each code-base needed to be written in a different proprietary programming language. And yet this is the current fragmented state of the industrial robot software space.

The herculean feat performed by the READY Robotics engineering team is the creation of drivers supporting robots from leading manufacturers such as ABB, Epson, Fanuc, Kawasaki, Staubli, Yasawa and Universal Robots. This driver development work was often in those proprietary languages, implementing support for sometimes thousands of error codes per robot, and up to ten thousand lines of code per driver - but the result is beautiful.

What is exposed to the robot application developer is a standard API, a single data schema, covering hundreds of models of industrial robots from major brands. They can rapidly create vendor-agnostic software using composable building blocks provided by the Forge/OS platform.

Through READY Robotics, the industrial robot software silos are broken.

While the hardware vendors might fear loss of lock-in through such software abstractions, the market opportunity that is unlocked benefits the whole industry - most of all the enterprises buying the robots. Now industrial robot data can flow to simulation tools, to ML training datasets, to predictive analytics, to virtual reality visualization apps, to IoT remote dashboards. Enterprises can benefit from modern applications and data-driven automation solutions.

Why manufacturing enterprises should care

Manufacturers today face unprecedented challenges:

- Onshoring manufacturing for supply chain resiliency

- Skills shortages at all levels (operators, controls engineers, robot programmers)

- Frequent changeovers to support high-mix production

While automation is well established in high volume production such as automotive, most production occurs in high-mix, low-volume (HMLV) manufacturing with some lines producing lots as small as 100 parts between changeovers.

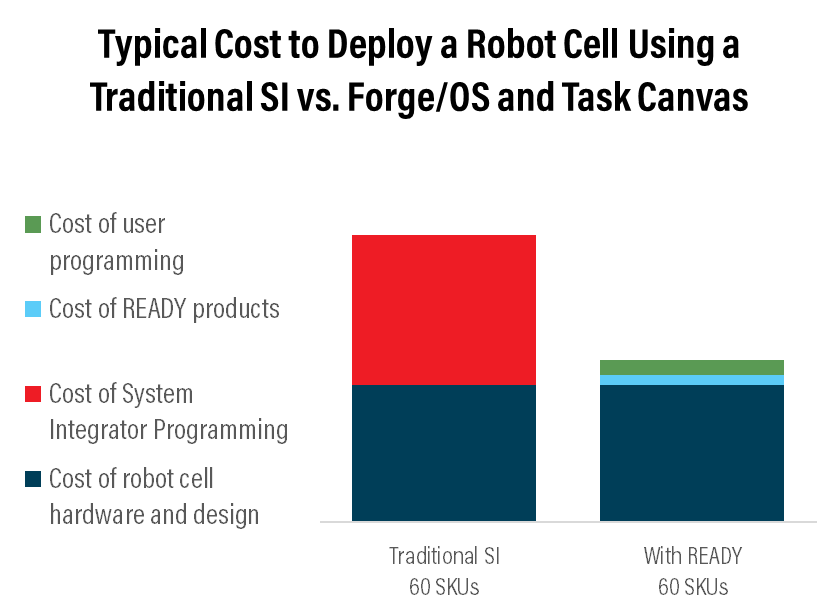

Given the current complexity of robot programming and dearth of experienced robot programmers, manufacturers who have automation tend to rely on robot systems integrators (SIs) that design, install, and program the robot work cell. To support a handful of different parts, the costs make sense. Beyond this, it rapidly becomes cost prohibitive to use a robot SI to do all the programming.

“The factory is the product” - Elon Musk

What manufacturers need are robotic solutions that are easy-to-use and flexible enough to reprogram without needing a highly specialized robotics programmer or controls engineer at the facility.

Empowered by this, enterprises can define automation solutions that embody their differentiation. They can also own the data that their automation processes generate in order to continually improve - and build the path to a sustained competitive advantage.

This is the future READY Robotics wants to help build with you.

Contact us to find more.

Sources

Microcomputer adoption graph data from Jeremy Reimer.

Meet us at Automate 2022

Experience READY Robotics and NVIDIA Omniverse Isaac Sim in action together at booth 2783 of Automate 2022 in Detroit, MI, from June 6-9.